Yesterday afternoon, I got a call from one of our institutional vendors, verifying our practice standards so they can make sure they’re marketing their product correctly. As I was chatting with him, I realized something.

You see, a lot of farmers get defensive when people start poking around, asking about their practices. As the gentleman asked me very industry-specific questions, I realized why that is. He was probing, judging, making sure we are legit. And yes, if we had something to hide, or if we had been misrepresenting our product, it would have made me nervous. Even still, we’re not perfect. We have a lot of plans on how to improve things out here. Matt and I are even bigger dreamers than we are doers, if you can imagine! There’s a whole lot of energy and vision living under this roof!

That said, we do not yet have it all figured out. There is no instruction manual for this kind (or probably any kind!) of farming, no playbook, no one-size-fits-all. Matt and I didn’t grow up farming, so we’re a few generations removed from our ancestors who did organic farming for their livelihoods, and we don’t have the inherited wisdom of days gone by. Even little things like learning the quickest way to put up a fence, the way to latch a gate, how to weld pasture skids, and the way to dig a hole. That knowledge has come by hard work and practice.

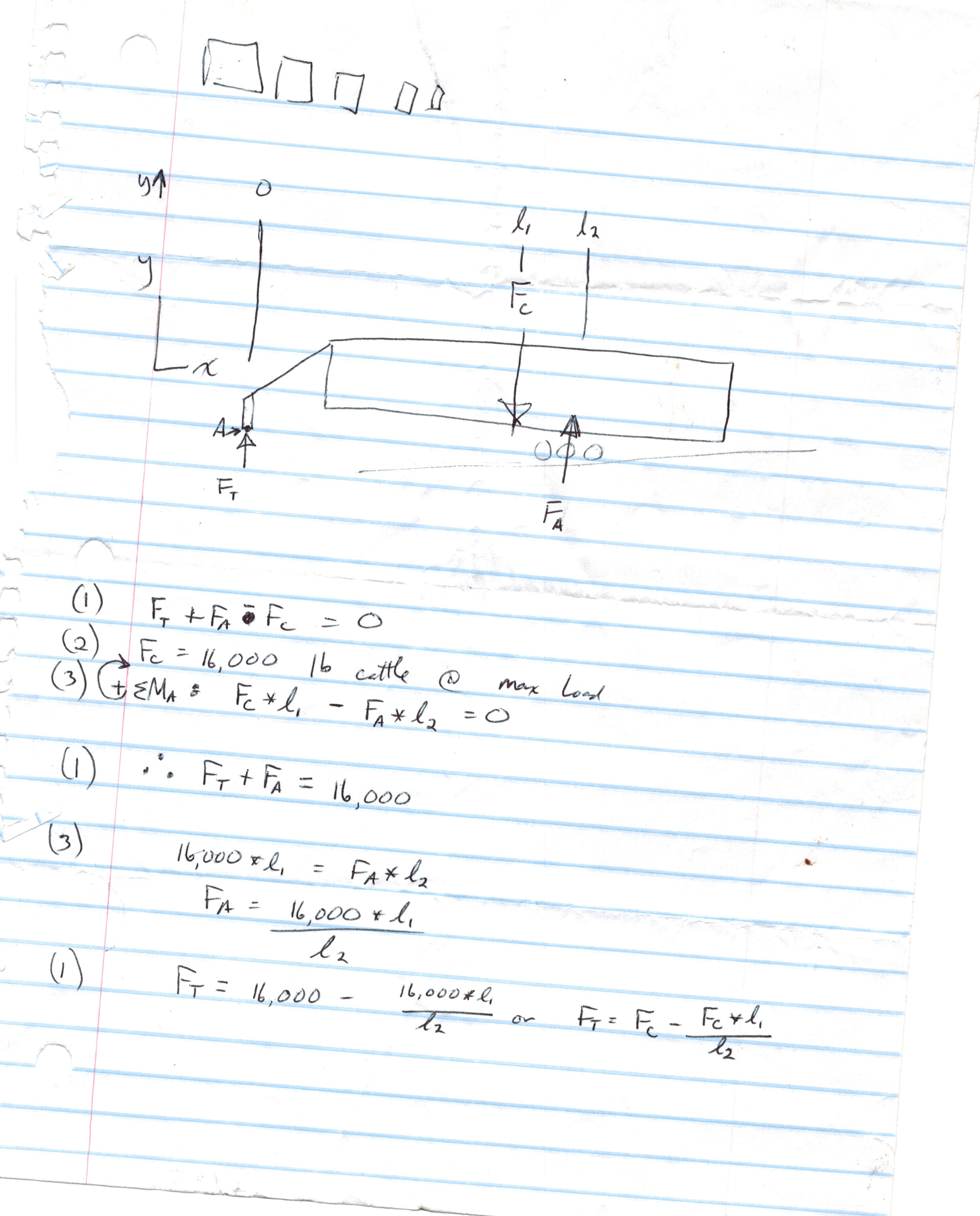

Matt’s latest creation is a pig-sorting box. When processing time comes, it’s quite a feat to separate breeders from feeders. Pigs don’t herd like cows, so this handy little contraption will help tremendously!

The specifics of natural, rotational pasture-based farming are vastly more complex. One contributing factor is the nuances of our situation. Our climate here in Jefferson, or more specifically, “Lassater Marion West,” experiences very different weather patterns compared with farms as close as 30 miles north or south of us. And of course, our specific animals, forest types, topography, and a million other factors, make certain things work well for us, and certain other things not work so well. But you know what–sometimes the only way you can figure it out is to try it. If it doesn’t work, try something else until you do figure it out.

Sometimes running our farm feels like flying a spaceship. There are umpteen control buttons, switches, levers, and indicators, and you have to pay attention to and manipulate multiple things all at once to keep things running. And so when someone asks a question like, “How do you manage the pasture for soil sustainability?” it’s equivalent to saying to us, “OK, write me a 40-page thesis paper on your short-term and long-term strategy for soil health as it pertains to pigs between the ages of 3 months and 4 years.” Rinse and repeat for all the other species in their various stages of life.

View that from the consumer’s end of things: questions regarding feeding practices, confinement, slaughter, humane practices… the list goes on and on. These are COMPLEX questions. And they need to be asked when you’re researching your food source.

But… There is no simple answer. Especially for folks who know little to nothing about farming. You can’t fit this kind of information onto a label in a store to ensure an informed 15-second purchase decision. It seems overwhelming! Grass-fed? 100% Grass-fed? Grass-finished? Organic? Free-Range? Hormone-free? No added antibiotics?? What’s a wary eater to do?

I saw a blip yesterday in Farm Bureau’s magazine that pointed out that most people have never set foot on a farm. How can you know a significant amount about a topic without ever having seen it? Would you be able to fully understand a cell phone if you’d never used one? Could you operate a car, only ever having read about it?

THIS is the reason we offer farm tours. SEEING and EXPERIENCING is so fundamental to understanding. Not that you’ll walk away an expert. But boy, will you be able to ask the right questions afterward. Things move from hypothetical to real. And since we’re dealing with our food source, I’d say that worth investing some time into.

So there’s my deep thought for the day. Put our next free farm tour on your calendar and come out and see us. March 25 at 10am. You’ll love it! And I hope you’ll be more convinced than ever that buying from a rancher you know is better than any label you see at the store!