I’m not sure what people envision exactly, when they think about the modern farm family’s daily farming tasks. It varies widely from farm to farm, of course, but for us, one task that we do very frequently together is collect and process eggs from our mobile-pastured hens. It’s a little more complicated than just scooping up a few “cackleberries” and putting them into cartons to sell. Because we really want to raise the hens on living pasture, it is imperative that the hens get moved to new ground often so they don’t kill the vegetation in their old paddock. Not to mention the intense manure build-up that happens when you leave any animal in one place for too long!

So we move the hens a couple of times a week, which means their house moves, too. Which means we have to travel to wherever their house happens to be to collect said eggs. But there are, oh, roughly 700 chickens laying in the ballpark of 500 eggs per day, which then have to be transported from the “wilderness” back to our nice, clean, dry egg-processing room. So that’s what we do each day at the end of the day after the chickens have finished their work and are preparing to settle in for the night.

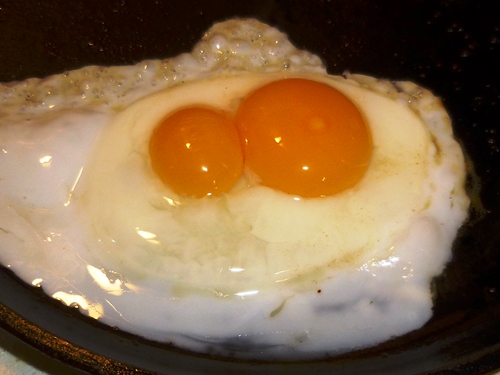

Unfortunately the hens don’t always get the memo that customers like clean, uncracked eggs with pretty little brown (or green!) shells. On rainy days (which have been in abundance this spring!), we tend to see a lot of mud tracked in from the field. I guess the hens didn’t learn to wipe their little dirty birdie feet.

So we do our best to field-sort the eggs into clean/dirty/cracked baskets, and then haul them back to the egg room for further inspection, cleaning, and packaging. Our jobs are further complicated by state requirements that we sort the eggs by size and “grade” (the size of the little air cell inside the egg). So after egg collection is when the real fun begins!

If you’ve been following our farm adventure recently, you know we have 4 young kiddos (oldest is 7!), with another on the way any day now, and we love to get them involved in what we’re doing… being that iconic farm-schooling family and all 😉 So the kids help us process eggs a few times per week, which, to my surprise, has been one of my greatest sources of pride and excitement about raising these little people into skilled, thoughtful, hardworking bigger people. My mommy-heart just swells with pride as I watch them grow in independence and self-confidence. You could liken it to polishing silver or something–it’s hard and takes a long time and a lot of elbow grease, but boy, is it gorgeous when it really starts to shine!

Anyway, I thought I’d take you on a fun photo tour of the Egg Room with the kids. Enjoy!

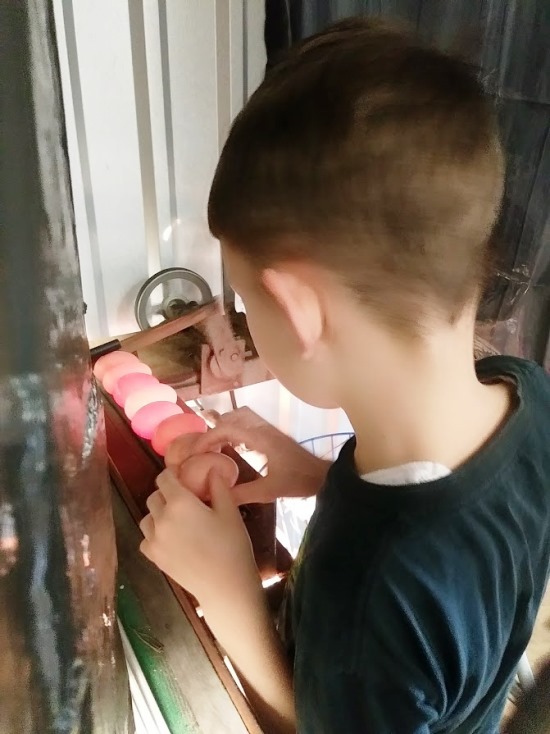

The first stage (after sorting) is washing the dirties. Axl works hard to keep his “hopper” full and helps alert us when a bundle of washed eggs emerge from the machine, ready to be transported to the next stage…

…then someone tall comes over and loads up the clean eggs from the conveyor and sets them in front of the fan to dry for a bit. Momma and Dadda usually tag-team this job. It’s a pretty fast-paced one because Axl is getting so good at loading up his egg-hopper!

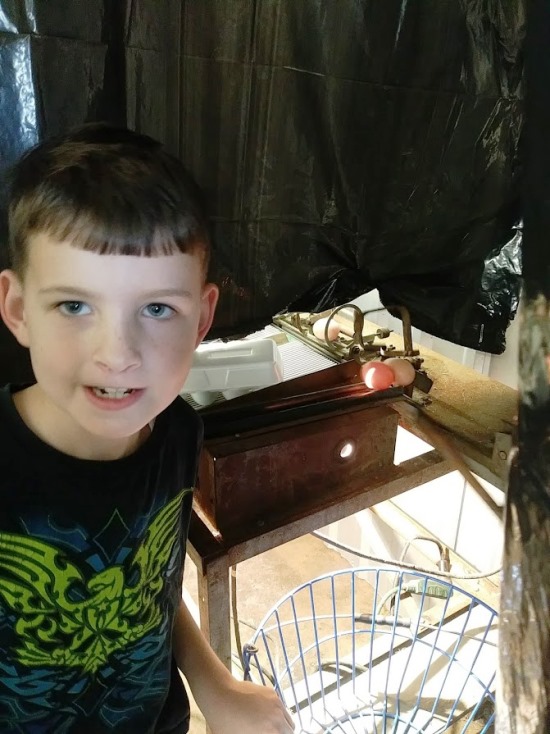

The next stage is checking for cracks and anomalies. Shevi is great at focusing on the job and making sure he gets eyes on every side of every egg. He’s now better at spotting cracks than I am!

In fact, he’s so good at the concentration element of his task, that when I kept pestering him to look at the camera, he finally said, “Hold on! I have to finish checking all the eggs!” Oh right. Great job, kiddo! Gotta love that 7-year-old cheesy smile! 😉

After the eggs get checked for cracks, they are individually weighed (by our handy-dandy 70-year-old all-steel grading machine!) and sorted by size. A human (in this case, me!) then does one last visual check and packs them into cartons by size.

Each carton is labeled and dated and then moved to refrigeration. That’s a lot of eggs! Good work, chickens!

You may be wondering about the other half of our children–the youngest half. Yep, they’ve been with us the whole time. Their job is to keep each other and the farm dog, Toby, company on the “front porch” of our little egg room.

We hope you enjoy eating the eggs as much as we enjoy producing them! Thanks for supporting real, family farms!