This Egg-ing Thing is Tough!

We’ve been raising laying chickens for going on 9 years now, and we find that the more we learn, the more there is to learn!

Early Lessons in Raising Eggs on Pasture

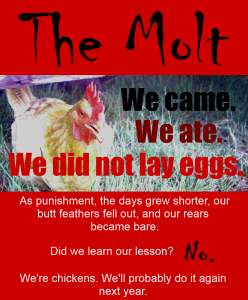

For example, one of the early lessons we learned is if you suddenly switch feeds on your hens, their bodies panic and they quit laying eggs and start making new feathers (aka molting) in case there’s going to be an extended food shortage.

Or if you buy baby hens (we call them pullets) with springtime as the target date for starting to lay, you’ll have eggs up to your ears, especially if it’s a mild spring. The thing is… so does everyone else—you can hardly GIVE an egg away! But by August when the weather turns really hot, there will be nothing!

So, learning from that experience one year, the next year you buy a batch of hens, aiming to have at peak production by July. Well, forget having eggs at Thanksgiving from those chickens! And they may or may not turn back on until springtime, so a backup plan is pretty necessary.

But it takes almost 6 months to get a chicken to laying age, and even the first few weeks of that, the eggs are teeeeny tiny as the hen’s system gears up to produce real, normal-size eggs.

Yep. In our extreme climate here in Texas, egg production is really unpredictable. No one can say what the weather will be up to 6 months down the road. Whether it will be a harsh, brutal winter or a mild one. A scorching, dry summer, or a lush, cool one. And for hens raised on pasture, it makes a big difference. And sometimes, here in Texas, those weather patterns come closer together than a body can reckon with!

She’s not getting older… she’s getting bigger!

Another interesting phenomenon is egg size as it relates to hen age. In general, during a hen’s life cycle, her eggs will gradually get larger as she gets older and puts on weight (it’s actually because her ovary—she only has one active one—grows larger as she ages). But there are seasonal effects, too. In winter, the hens tend to eat more feed to produce more body heat, and so their eggs will be larger. In the dead of summer, they drink a lot more water but eat less feed, so they will still lay large eggs, but fewer of them. In spring and fall, when there’s lots of grass and bugs to nibble, the eggs will tend to be smaller. Take a snapshot at any given time of year and of any given batch of hens, and you’ll see a wide variety in distribution of egg size.

Crazy, huh? Even crazier when you’re a direct-to-consumer farm and all the eggs you’ve got to sell are the ones your chickens are laying. To say it another way, if your hens are only laying very small or very large eggs… that’s all there is!

How does this all compare to a commercial egg operation?

A typical commercial egg farm might have around 7 million hens. They could collect 5,000,000 eggs or more PER DAY during the peak season. To put this into perspective… it would take us 57 years to produce as many eggs as they can produce at just one farm in one day!

There’s nothing inherently wrong with being big, of course, but to do really-pasture-raised at that scale would be pretty doggone difficult. Theoretically it *could* be done. But most of us who are really-pasture-raising our hens are MUCH smaller operations.

It’s not that the giant egg farms don’t have to deal with these seasonal issues, although keeping the hens indoors can help keep the temperature and lighting much more uniform throughout the year (for better or worse…). I’m sure their hens still produce pullet-size eggs for a time, and some eggs are weird shapes, and some eggs are double-yolker jumbos and some have stains on the shells… But supermarket-shopping consumers never see these anomalies and extremes of production, so it seems as though they must never occur.

The reality is… when you’re THAT BIG, you have access to a wider variety of markets. If your eggs are too small or too big, you can sell to the liquid egg/dried egg/processed food market. If your eggs are not Grade A (like if the shells are misshapen or have stains), you can sell to institutions like cafeterias, delis, restaurants, food distributors, etc. If your eggs have cracks, there are special markets for salvaging those. Those of us who sell direct really can only sell premium eggs in common sizes. It’s really hard to sell pullet-size and jumbo-size to the average customer.

If you’re a small fry like us, but bigger than just a backyard farm, you produce too many “weird” eggs to eat yourself, especially during those transition phases, which are amplified when the hens are having to deal with real weather patterns. So you have to come up with strategies to try to balance things. But sometimes nature is unpredictable, and there are LOTS of factors that affect outcomes.

Pickled Eggs!

We’re in that sort of a pickle right now, as you can tell from our online farm store. The older batch of hens is going through a molt, so though they’d be laying larger eggs right now, they’re taking a break for the summer.

The younger recruits are stuck in pullet/small phase! So we have lots of eggs… but they’re all tiny!

Nine years of egg production, and we still feel like rookies. Ha! Just goes to show you that farming is like parenting. You don’t know how to do it until after it’s over. 😛

What’s an SGR Fan to do?

Y’all hang in there with us. And buy a few extra eggs to make up for the smallness. The small ones are big on taste! 🙂

How to substitute small eggs in recipes

Small eggs are ¾ the size of larges. The easy way to say that is that for every 3 large eggs called for, use 4 smalls. Or you can just multiply the number of larges times 1.5, and that’s the number of smalls you need. Pullet eggs or “peewees” are 5/8 the size of larges. They’re just a smidge bigger than half a large egg. Most recipes are not so finicky that you can’t just pretend that 2 pullet eggs equal 1 large egg. If you get into some huge volume recipe like a soufflé or custard, I’d suggest using the 5/8 (5 larges = 8 pullets) conversion. But if you’re making soufflés and custards… you probably don’t need me to explain this. 😉