Farming provides an almost endless supply of hilarious inside jokes and quotable little sayings. It seems we live very much “on the edge” and “by the seat of our pants,” never knowing what challenges the day will bring. One of my favorites you can find on various t-shirts and mugs, and it reads something like this, “I’m sorry for what I said while we were working cows.”

The average city-slicker doesn’t really know what it means to “work cows,” and I suppose it varies from farm to farm.

Since, unlike the very large majority of cattle farms (even many of the self-named “natural” ones), we don’t use pharmaceuticals routinely in our cattle, the only real reason we would need to move a bunch of them through the cattle chute all at once is to do some annual herd maintenance, such as when we need to castrate young bulls that aren’t ideal for breeding, or to put on ID tags on the new calves so we can track genetic lines and better manage our herd, and to check exposed cows (as in, “exposed to bull”) for pregnancy status. So that makes for roughly twice a year that we “work cows” as a scheduled thing, and the chute provides a safe restraining location so we can perform necessary procedures and nobody gets hurt.

But actually, we weren’t even really performing procedures this time, so we didn’t use “the chute” at all. We just used the working pens, which are sturdy, permanent cow-proof enclosures with lots of closeable exits and holding pens. Very convenient for sorting live animals the same size as a small car!

Our mission: To separate eligible breeding females (and their unweaned calves) from the rest of the herd in order to turn them out to pasture with the bulls!

So why wouldn’t we just breed every female available? I guess you’re about to get a crash course in cattle-breeding 101!

There are many possible reasons we might remove a breeding-age female from the breeding herd. Disqualifications might include things like lack of motherly instinct, poor milk production (no, we don’t milk the cows, but we can tell if they produce adequate milk because of how well their calves grow!), or just plain-out crazy behavior. One nutso cow can make the whole herd nervous and difficult to work with. And interestingly… it turns out that most of the time, their calves grow up to be nutso, too! So we tend to file those in “freezer camp candidates” to make everyone’s life less stressful.

Another little management tidbit is that we do not allow our females to breed until they’re at least 2 years old. Younger than that, and their frames just aren’t developed enough to deliver a healthy-size calf, and they may also have difficulty with milk production once the calf is born.

That means the yearling females “freeload” for an entire year (actually more like 2 years!) while they wait their turn to join the momma herd. What happens to the yearling bulls? Well… there’s no such thing as a chastity belt for cattle, so we go ahead and “promote” the year-old bulls to bulls right along with the big fellas, and that goes just fine. Do they fight? No, actually. They get along fine!

Humorously, the bulls freeload for most of their adult lives. They actually only “work” for 2 months out of the year. This is not typical of beef operations. A lot of producers allow their bulls with the herd for 6 months or more in order to improve calving efficiency and to space out calving over two seasons. But we like a nice tight breeding window so all the babies are born after risk of severe winter weather, but before the intense spring grass growth takes off, lest the babies grow too quickly inside their mommas and make calving more difficult than necessary. Anyway, that means bulls go in for two heat cycles, starting first of July. They stay with the cows 60 days, and then they go on vacation until the next summer!

So during that 2 months, we have to get all the yearling heifers, cull cows, and other misfits, out of the breeding herd, and the best way to get that done is using the sorting pens.

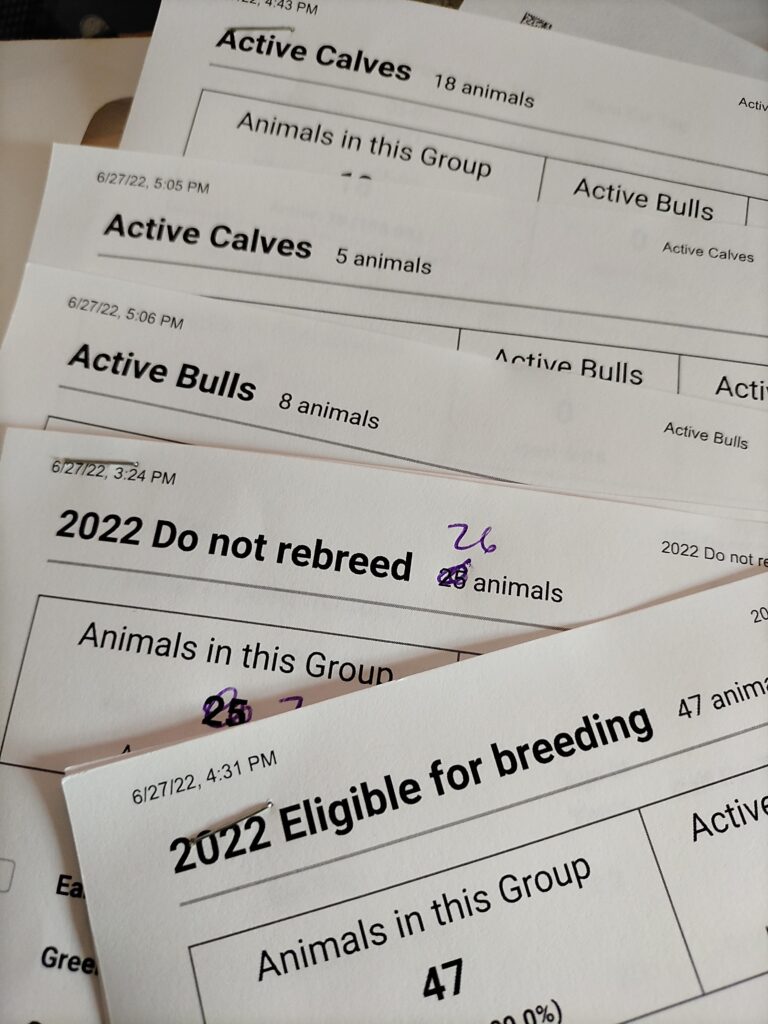

A few weeks ago, I logged on to my online cattle-tracking software and printed a big list of cows and 2-year-old heifers we want bred and the tag numbers of their unweaned calves. Some of the calves are only 3 months old, so it would be very bad if we accidentally separated them from momma too early. Then I made a big list of all the not-for-breeding females and THEIR calves (because even though they aren’t on the list to produce a 2023 calf, we’d like them to finish raising this year’s calf!). Then I made a list of the yearling heifers, etc, and got everything all squared away. We really like this cattle tracking software and make notes throughout the year of any distinguishing characteristics about specific animals, so that helps when the decision-making time arrives of who to keep or not.

I had all my paperwork ready, and I knew that Matt would suddenly say to me some unknown morning, “I’m going to separate cows today.” That’s how he rolls.

Now, he could probably do this cattle work by himself. He’s pretty good at running a highly minimalist farm. But I insisted on helping him. He at LEAST needed a gate-opener! So I had my papers ready. I had my boots ready. And sure enough, one morning, off we went to play with the cows!

I would like to emphasize that, like most things that go from theoretical to actual, cows-on-paper is MUCH easier than cows-in-real-life. So often they’ve lost ear tags or want to stick with a particular herd-mate, so sorting is “interesting.” We have a backup ear tag that’s a little metal clip that stays put very well, but our cows don’t like being in that close of contact with their human bosses, so there’s really no way to get eyes on it when they’re out in the open. But Matt knows his cows. He deals with them every day, after all. Even so, the lists really help!

I am happy to report that no apologies were necessary after cattle working. We’ve been married more than 16 years now, and you learn how to respect one another and work as a team. But there were still some silly little quips overheard during cattle working:

“There’s a good chance there are wasps in this ragweed so if you feel a sting get out of there quick!”

“Come on. Let’s go. You can poop later.”

“She won’t go by herself. She’s only got one good eye and she’s nuts.”

“Why don’t we just eat her?”

“That’s a good idea.”

So there you have it. My contribution to cattle work was suggesting to eat Number 513. I’m more of a journalist than a herdswoman. But I like being a help to my hubby even if it means I just open the gate every now and then. Matt did the hard stuff. I just enjoy seeing our cows!