It seems the 13-year mark of small business is when all your equipment decides to break down, especially if most of it was already almost a decade old when you started (but of course we didn’t own much “new” stuff. We like our equipment already “broken in,” ha!). We’ve had to do a boat-load of repairs this year. Matt says we can start calling him Jack, as in Jack of All Trades, Master of None. Thankfully he’s super handy and this last decade-plus has taught him a whole bunch about fixin’ stuff, and fixing it fast! He’s a pretty useful fella these days… Guess I’ll keep him. 🙂

It all started during our July delivery to Longview and Marshall. On the way to Longview, we heard some rather icky noises coming from the undercarriage of the Hambulance (our farm delivery vehicle which is a 21-year-old retired Red Cross food distribution truck). He pulled over several times to check things and try to identify where the noise was coming from. Thankfully we try to budget extra time into our delivery days for just such occasions as these when our old farm vehicles are feeling needy.

Matt determined it was non-critical and coming from the e-brake, so he temporarily disabled it and we managed to get through our drops and get back home. One funny excerpt from the day was when Matt said, “Well, it seems my speedometer has suddenly stopped working!” Trifles! Ha!

Now that happened to be our last delivery of July, leaving a full 2 weeks to investigate, order parts, and make repairs. Driving older vehicles has certain advantages. Things are still mostly mechanical and so can be repaired without much extra technology. But the downside is that at some point the parts become obsolete and hard to find. One of the main parts was on backorder, but amazingly was able to ship out ahead of schedule. Whew!

Matt diligently went to work as often as he could to get the ambulance drive shaft taken apart, busted parts removed (turns out it was a toasted transmission-mounted e-brake bearing… two of them, actually), and new parts ordered. But he had plenty of other stuff to do as well, including rounding up a bunch of turkeys for processing on Monday morning of our “off week” of July. That happened the same Sunday night when I noticed our egg cooler was not quite down to normal temp when I stopped in to grab some eggs for the next morning’s breakfast. It would not have been unusual except that Sundays there is no in-and-out of the egg cooler like the rest of the week, and so no reason the temp should have risen at all.

As a precaution, we moved the most thermally fragile products out and Matt checked out the unit and made some adjustments. Again, thankfully Matt has learned so much through these years of shoestring business ownership. Our local refrigeration expert finally retired a few years ago (in his 70s???) but had mentored Matt along the way to help him be able to do many of his own maintenance things on refrigeration.

Monday morning the temp had not recovered, but still was in the safe range, and we had to switch gears and deal with turkey processing, which would take most of the day. We took the whole family down with us and everyone did a stellar job. Forty more gorgeous turkeys in the freezer! We’ll be releasing these into inventory soon….

Meanwhile I had posted info about our farm store job opening, so we were getting all sorts of calls and emails about that. Eeek! Emails and messages were piling up and I was busy bagging turkeys! And Matt was due to receive 1600 baby broiler chicks on Wednesday morning and still had a brooder house to prep for that. But out of nowhere, our hatchery called and asked if they could delay this batch until Monday of the following week. YES PLEASE!

Monday evening we decided to move everything out of the egg cooler, so we stuffed eggs into every refrigerated space we could find on the farm. Here’s how you fit 3 cases of eggs into a single fridge shelf:

I was getting nervous because I had placed a big order with Azure Standard, our main dairy supplier, and had about 350 pounds of delicious cheese and butter headed to me on an 18-wheeler with no way to cancel or postpone it, and I only had about 48 hours to figure out what to do with it all with no big walk-in cooler. I’m going over options in my head. Could I rent temporary cooler space in a local restaurant? Do I need to find a commercial cold storage place in a bigger city like Shreveport or Tyler? Should I go to Lowe’s and buy a couple more refrigerators? Even then, how would I get them home? Our ambulance was still down for repairs, and of course Matt was busy trying to repair the egg cooler and it didn’t make sense to stop to drive to town to buy fridges or move product off site. We even considered routing some freezer air into the cooler, but any stop-gap solution only stole time from getting the real solution accomplished. We would proceed with the repair.

Matt got the parts picked up Tuesday morning and started repairs. By Tuesday afternoon he had everything installed and was ready to test it. Now it was a wait-and-see game. I packed up my frozen orders that would be going to Tyler that week (it was a relief to know the freezer was still working after June’s fiasco!). I wondered how we would pull that off—our only other delivery-worthy vehicle was the 15 passenger van, but a normal Tyler order collection simply wouldn’t fit in there unless we removed a couple rows of seats (more time away from the solution!). The ambulance repair was close, and the remaining parts arrived Saturday and Monday, but now Matt was busy dealing with this even-more-urgent egg cooler issue.

Suddenly I had an idea! I could split up our Tyler drops and drop off Granary’s order a day early. This would solve both the issue of not having a large enough running delivery vehicle, and it would offload 10 cases of eggs, freeing up just about the exact amount of refrigerator space I would need for my Azure order. I contacted the manager there to make sure that was ok, then I loaded up the kids and we did it all in one big loop—dropped off Granary, and headed to Marshall to pick up our order from Azure. Matt stayed home to continue monitoring the cooler. I stopped in to say goodbye to him and he looked a little frightened when he saw me, and asked, “What??” I said, “I came to tell you goodbye!” He sighed, “Oh, I thought you were going to tell me something was wrong with the van!” Poor guy is a little shell-shocked, I guess!

Off we went and Matt finished up his repairs. The cooler temperature was finally dropping! When I got home, I did my employee interviews and hired Kathryn!

The next day we drove to Tyler again to meet up with our customers. It was kind of neat because we got to take all the kids with us in the van and make a bit of a family day of it. The really neat thing about this business is that it does involve the whole family, and our hope is that the children will grow up and become your farmers, too, right alongside us, and then continue carrying the torch with their own families someday if they so choose that path.

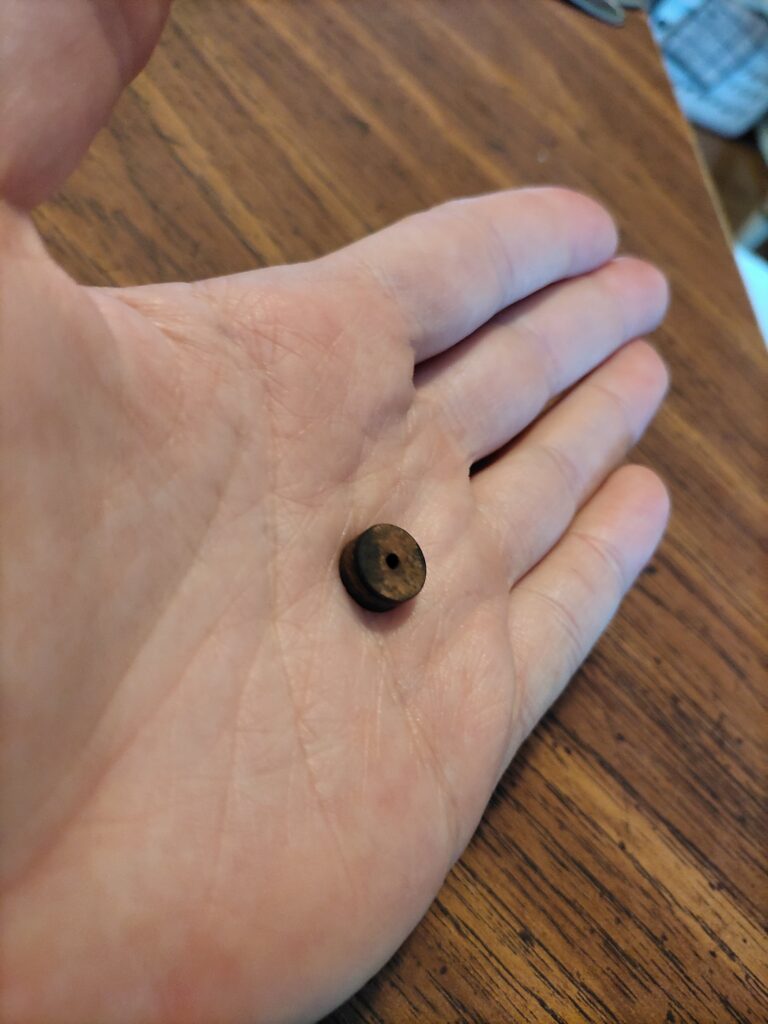

What was wrong with the egg cooler? Well, actually, this particular condenser/evaporator setup was given to us (it needed some fixing up), so it was already a little old. (Fits right in with the rest of the equipment, I suppose…) Matt replaced all the replaceables and was able to identify where the malfunction was, although it was rather puzzling. Turns out that the previous owner had it sort of “throttled down” by using two methods of restriction, rather than the usual one. Matt was amazed that he was able to find it. Just this little tiny thing called a restrictor. Looks like a fat copper washer. The cause of all the trouble. I guess the heat and age finally just got to the whole system and caused a breakdown!

We are praising God for watching over all these details this week as He always does. So that’s a little glimpse of what it’s like around here. Might help explain why we sleep so soundly at nighttime. God’s got this all worked out. We just keep putting one foot in front of the other!

Thanks for sharing the adventures of what it’s like to be a farmer. I admire y’all and am so glad to see God’s faithfulness in carrying you through many difficult situations! May He continue to bless you and keep you and increase your faith in him!

Blessings to you both! I really pray and hope things are sailing along now, and yes, I understand about old parts and repairs that are sometimes needed, darn that ole entropy. Sure pays to have a handy guy around.

Wishing you both well, and hoping that things are up and running. Would love to hear more updates.

Wishing God‘s continued blessings on you and all your family.